The Livingston research laboratories have a wide range of state-of-the-art equipment for membrane design and testing, chemical synthesis, process optimisation and piloting as well as process simulation and scale-up. In addition to testing commercially available membranes and new applications, our researchers have the expertise and facilities to fabricate novel membranes within our membrane fabrication labs. Our laboratory capability enables us to demonstrate proof-of-function of fabricated membranes under a broad range of real processing and operational conditions.

Some of our equipment is funded through research grants for specific research programmes, whilst other facilities are strategically funded by the Group.

Our key equipment includes:-

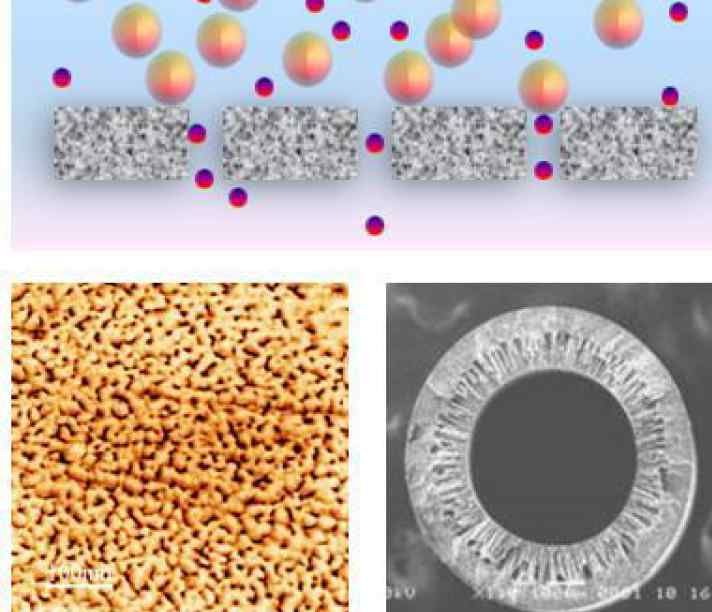

- Membrane casting machines

We have a bench membrane casting machine to fabricate flatsheet membranes (50cm x 30cm) on different backing fibre cloths. We also have a continuous casting machine to produce flat sheet membranes up to 30cm wide and up to 100m long with controlled temperature of the phase inversion bath.

- Membrane coating machine

Used for the synthesis of flat sheet polymeric membranes. Membranes are coated with a thin film of polymer solution followed by the immersion of the films in a coagulation bath to obtain the final membrane via wet phase inversion.

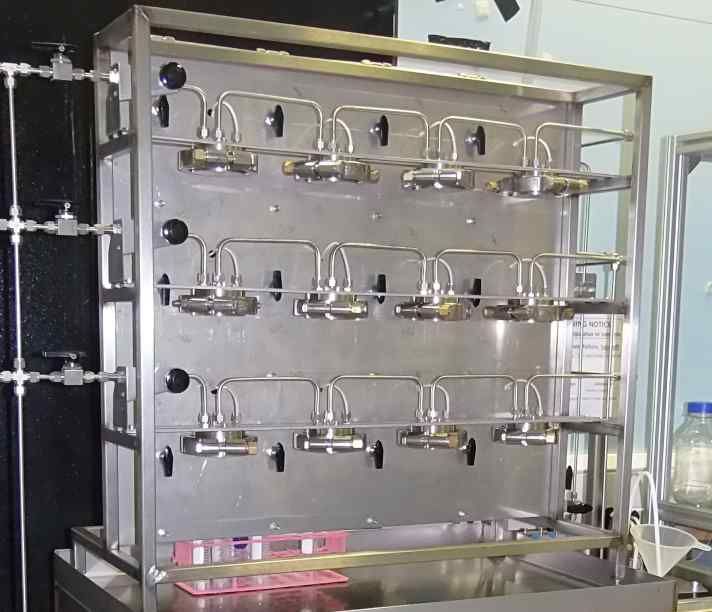

- Bespoke laboratory cross flow membrane testing rig

We have a 12 cell cross flow membrane testing rig which can test membranes under operating conditions with pressure up to 60 bar and flow rate up to 200 litres per hour.

- Zeta Potential Analyser

Our surface charge analyser measures the zeta potential of flat sheet membranes (films) from pH 2-10.

Other equipment

Within the Department our researchers have access to a purpose built modern analytical services lab which is home to more than 20 major analytical instruments and a collection of useful general laboratory equipment.